Filter 0

Application

0Market

0Technology

0Flow Rate, Maximum: gpm

0

Barrier™ Ti UV System from ETS-UV™ Product Family

Our latest low pressure UV solution delivering improved water quality for hotels/resorts, swim schools, ponds, water features, and other small aquatic facilities.

Delta UV products have been discontinued. For technical support and consumable parts, contact us at 855-267-9201 or delta-uv@xylem.com. For commercial applications, please contact us for details of our new Barrier Ti UV System.

ETS-UV™ Disinfection Generators - VX Range – Mini & Midi

Introducing the latest low pressure range of UV for superior disinfection of industrial water in a range of applications. High quality UV systems for operational flexibility and performance.

ETS-UV™ Disinfection Generators - SW Model

Compact, Medium pressure in-line UV Systems for the disinfection of process and wastewater

ETS-UV™ Disinfection Generators - SX Model

Compact, Medium pressure in-line UV Systems for the disinfection of drinking water and industrial process water

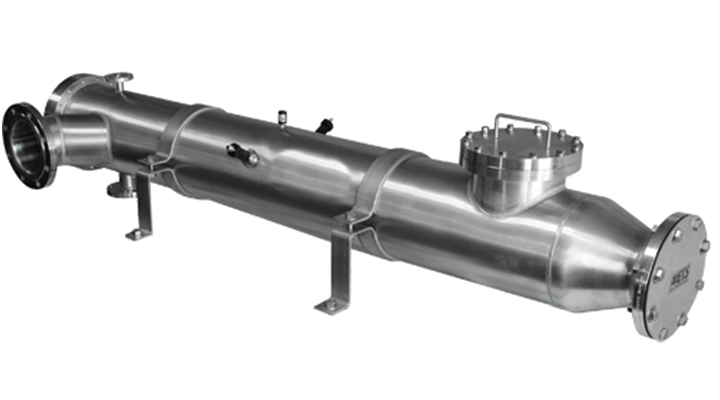

ETS-UV™ Disinfection Generators - UVLW Model

Closed Vessel Low-Pressure UV Systems designed for municipal wastewater treatment and industrial wastewater discharges

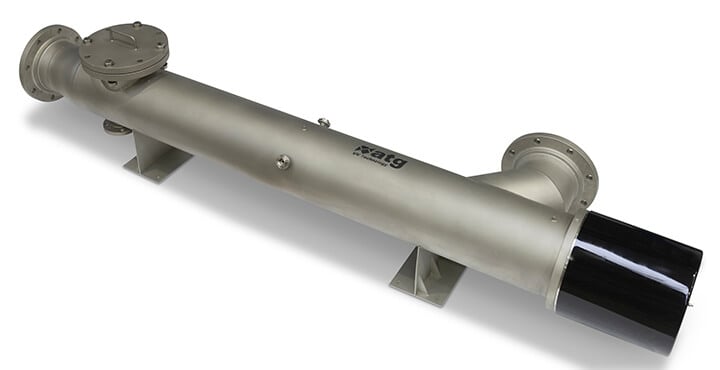

ETS-UV™ Disinfection Generators - UVLX Model

Ultra High Output Low Pressure UV system designed for municipal drinking water

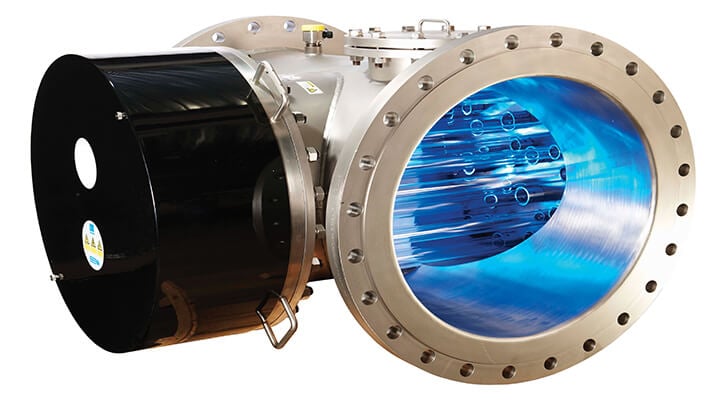

ATEX Certified Explosion Protected Generators

Packaged UV generator option used where hazardous, explosive environments exist

ETS-UV™ Skid/Containerized Systems

ETS-UV™ generators incorporated into enclosed containers and skid packages that offer immediate plug and play use.

ETS-UV™ Generators – VT TOC

Introducing the latest low pressure range of UV for superior treatment of industrial water in a range of applications. High quality UV TOC reduction systems for operational flexibility and performance.

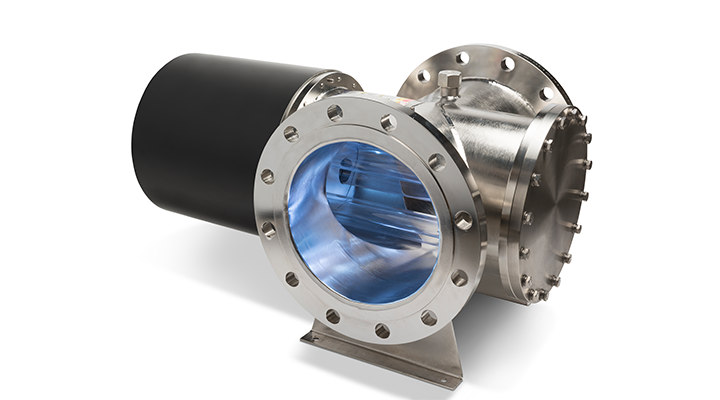

ETS-UV™ Disinfection Generators – VXM Range

Our latest medium pressure UV offering designed for superior treatment of industrial water in applications requiring performance at low UV transmittance or requiring high doses.